How to Dimension Threads on a Drawing TUTORIAL

Threaded fasteners

Fastening is a method of connecting or joining two or more parts together, using processes or devices.

- Processes: welding, gluing, soldering;

- Devices: bolts, screws, anchors, etc.

One of the most common methods used for fastening is mechanical fastening, a procedure that uses manufactured devices such as screws, pins, or rivets to hold parts of an associates together. A threaded fastener is a mechanical fastener used to bring together ii or more parts.

Thread specifications: English language system

To specify a thread using the English language system, you lot must provide a minimum of five pieces of information:

- Thread form

- Thread series

- Major diameter

- Class of fit

- Threads per inch

Thread form is the shape or profile of a screw thread. Many types of thread forms have been developed.

- The sharp-V thread was originally developed by William Sellers (September 19, 1824 – Jan 24, 1905), a mechanical engineer, manufacturer, man of affairs, and inventor who filed more than 90 patents.

- The American National thread replaced the sharp-V thread and is stronger than the abrupt-5 thread.

- The Unified thread is the current standard used in the United States, Canada, and England.

- A variation on the Unified thread is the Unified National Round thread, abbreviated UNR.

- The metric thread is the international standard thread, like in shape to the American National thread.

- The square, Summit, and buttress threads are used to transmit ability in gearing and other types of machines.

- The knuckle thread is usually rolled from canvass metal or cast, and it is used for lightbulb bases, bottle caps, and drinking glass jars.

The thread serial refers to the standard number of threads per inch, and there are four classes: coarse (C), fine (F), actress fine (EF), and constant pitch. When used with the Unified thread, they are abbreviated UNC, UNF, and UNEF. The constant pitch series is specified by writing the number before the form designation (iv, 6, 8, 12, 16, xx, 28, 32).

- Coarse series fasteners are used for quick assembly or disassembly of bandage atomic number 26, soft metals, and plastic, and are designated NC or UNC.

- Fine series fasteners are used when a swell deal of force is necessary for associates, and are designated NF or UNF. These fasteners are used extensively in the aerospace and automotive industries.

- Extra fine serial fasteners are used when the length of engagement is brusk and the awarding calls for high degrees of stress.

- Constant pitch serial threads are for special purposes, such as large-diameter or high-pressure level environments. It is used when the Coarse, Fine, Extra-Fine Series do not meet the pattern requirements, and within these series, preference should exist given to the 8, 12, and 16 thread serial.

There are 3 classes of fit established by ANSI for general use.

- Class 1 - a loose fit where quick assembly is required and looseness or play between parts is acceptable.

- Form 2 - a high-quality, general purpose, commercial class of fit for bolts, nuts, and screws widely used in mass product.

- Class 3 - a very loftier-quality threaded fastener with a shut fit, used for precision tools and for high stress and vibration applications.

Threads are only symbolically represented on drawings; therefore, thread notes are needed to provide the required data. A thread note must be included on all threaded parts, with a leader line to the external thread or to an internal thread in the round view.

External thread notes are given in the longtitudinal view. Internal thread notes are given on the end view, with a arrow to the solid circle.

A thread note should contain the following data:

- Major diameter in fraction or three place decimal form.

- Number of threads per inch, followed by a space.

- Thread course designation.

- Thread serial designation.

- Thread class designation (1,2, or 3).

- Internal or external symbol (A is for external threads, B is for internal threads), followed by a space.

- Qualifying information, such as:

- LH for left hand threads. If the thread is right-hand, RH is omitted.

- DOUBLE or TRIPLE for multiple threads.

- Thread length.

- Cloth.

Thread specifications: Metric arrangement

Metric thread specifications are based on ISO recommendations and are similar to the Unified standard. The bones designation for a metric thread are:

Hither, the notation specifies that the thread is metric (M), the diameter of the thread is sixteen millimeters, followed by the multiplication sign 'x', and the pitch is ane.5 millimeters.

Generally, a complete metric thread note should incorporate the following information:

- Thread course symbol. The letter M is used to designate the metric profile. The J profile class is a modified Grand contour.

- Nominal size (basic major diameter) in millimeters, followed by an '10'.

- Pitch in millimeters, followed past a nuance. The pitch tin exist eliminated for coarse threads, merely it is preferred in the American employ of the standards.

- General purpose tolerance. The tolerance form designation includes:

- Pitch diameter tolerance: class, position

- Small-scale diameter tolerance: grade, position.

For external threads tolerance lowercase letters are used, for internal threads – uppercase letters.

Screw thread representation

Two types of conventions are in general utilize for screw thread representa tion , conventional and alternative (pictorial) representation.

Conventional Representation should exist used whenever it communicates the required information without confusion, every bit it requires the least amount of drafting effort.

This method is contained of the type of screw thread. The blazon of screw thread and its dimensions have to be indicated.

The alternative representation requires more drafting time but is sometimes necessary to avoid confusion with other parallel lines, or to more clearly portray particular aspects of the thread. This is a close approximation to the bodily advent of the screw thread:

Information technology is simplified, then that crest and roots for total threads are shown sharp, with single direct lines instead of the double curved lines that would be required for the flat crests and roots.

Culling representation should exist used only for enlarged particular and other special applications.

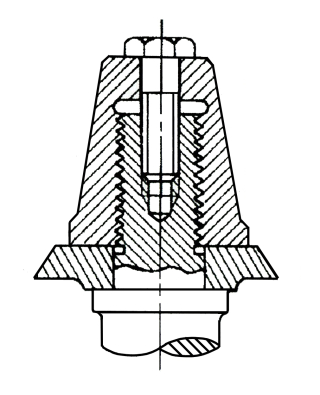

Threaded assemblies

For general apply, the conventional representation for assemblies of threaded parts is recommended.

In sectional views, the externally threaded part is always shown covering the internally threaded function (bolt thread is shown, hole thread is not shown).

Both methods can be used simultaneously on the same cartoon.

Rolled threads

External threads may be cut using a Die.

A Tap is used to cut smaller diameter internal threads.

However, in that location is also a type of threads which is non being cut, but rather beingness rolled.

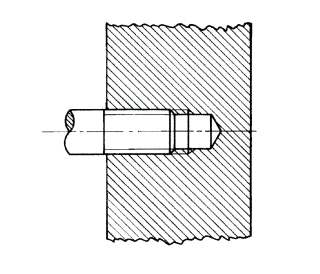

Rolled threaded products are often made with a reduced body diameter, approximately equal to the pitch diameter. When it is necessary to show this, the characteristic may be fatigued as shown:

Here the thread is depicted bigger than the diameter of the function (both, in conventional and in alternative representations).

DOWNLOAD HERE

How to Dimension Threads on a Drawing TUTORIAL

Posted by: margaretfroweed.blogspot.com

Comments

Post a Comment